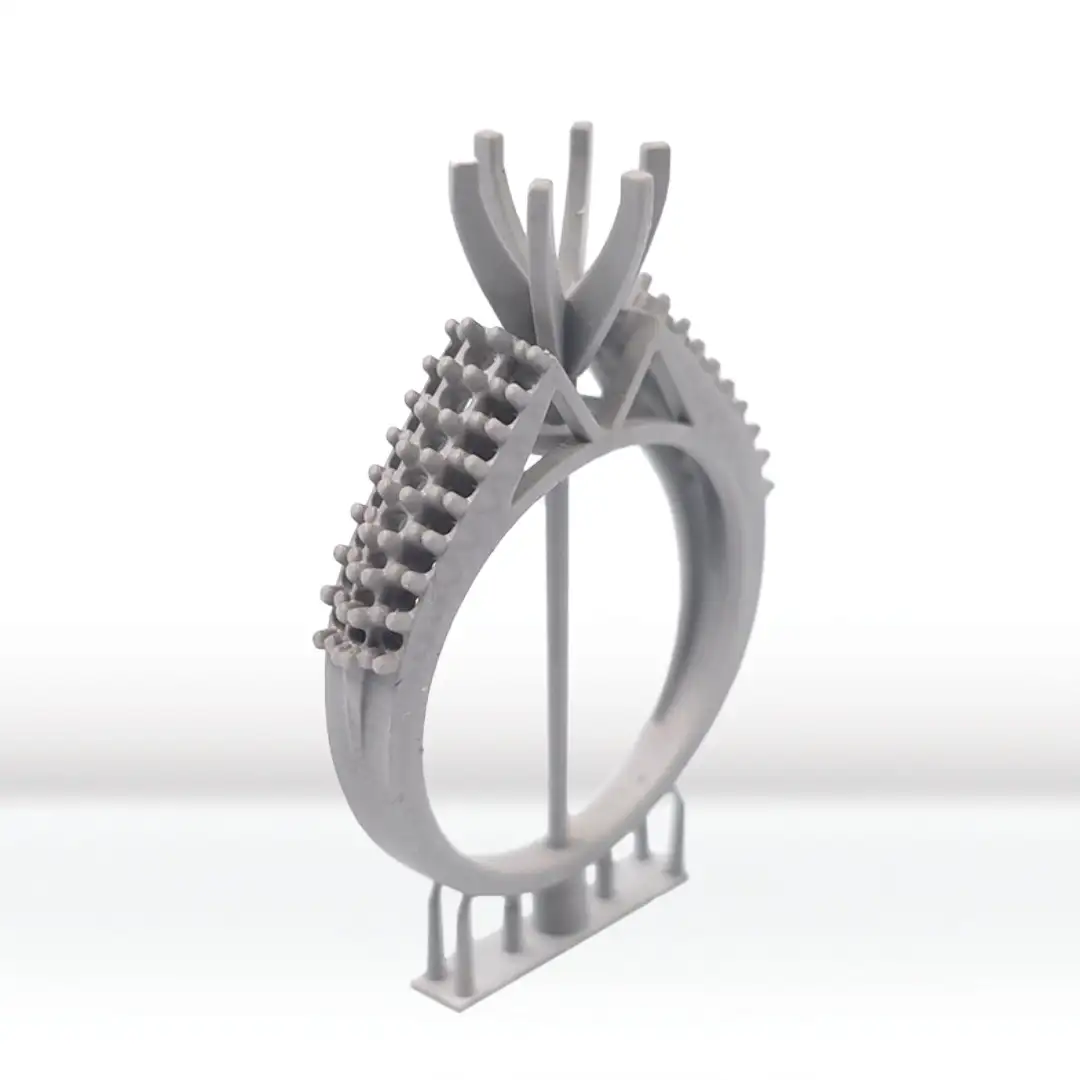

4Melt Castable Resin is the Perfect Resin for Entry Level to High-Production workshops. With its Wax like melting Properties it able to Cast Most challenging Solid parts, Thick Gauge Men’s Rings and Other Thick Jewelry Designs with Ease.

-

Solid Designs

-

Fast Melting

-

Smooth Castings

-

No Shrinkage

Information

Technical Details

| Filigree | Fusion | Standard | Solid Parts | Chains | |

|---|---|---|---|---|---|

| Printability |

Filigree

|

Fusion

|

Standard

|

Solid Parts

|

Chains

|

| Castability |

Filigree

|

Fusion

|

Standard

|

Solid Parts

|

Chains

|

| Property | Value | Standard |

|---|---|---|

|

Property

Density |

Value

1.08 gram/cm3 |

Standard

ASTM D1475-13(2020) |

|

Property

Tensile Strength |

Value

3.84 MPa |

Standard

ASTM D638-14 |

|

Property

Flexural Strength |

Value

7.06 MPa |

Standard

ASTM D790-02 |

|

Property

Flexural Modulus |

Value

155.89 MPa |

Standard

ASTM D790-02 |

|

Property

Shore D Hardness |

Value

58 |

Standard

ASTM D2240-15(2021) |

|

Property

Viscosity |

Value

9.53 Seconds |

Standard

DIN 53211-4 |

|

Property

Color |

Value

Grey |

Standard

- |

Printing Instructions

- Make sure to Pre-Heat up to 45C the Resin and shake the bottle for 30 seconds before pouring into the Tray.

- If the Resin is sitting on the tray for longer Periods, Make sure to Mix it with Silicone Spatula Timely.

- It is a good practice to filter the Resin after every Job.

Washing & Curing Instructions

- Use Ethyl Alcohol 99% for washing the prints..

- When using an ultrasonic cleaner, run a 5-minute cycle with the heat turned off (recommended procedure).

- Always use compressed air for drying the printed models.

- For simple immersion in an alcohol bath, wait approximately 10 minutes while the prints are submerged if using IPA reduce washing time.

- After the initial washing step, spray brand new 91% to 99% ethyl alcohol or IPA onto the patterns and dry them again to improve casting quality.

- Ensure that the printed model is free of any residual resin or alcohol after washing and drying.

Burnout Cycles

BURNOUT CYCLE #1

(Recommended for flask sizes less than 50.8 x 76.2 mm (2” x 3”))

- Load flask into room temperature oven, and ramp to 150°C (302°F) over 30 minutes.

- Hold at 150°C (302°F) for 3 hours.

- Ramp to 750°C (1382°F) over 3 hours.

- Hold at 750°C (1382°F) for 4 hours.

- Reduce oven to flask temperature for casting.

- Hold flask temperature for casting for 2 hours to stabilize temperature throughout the mold.

- Cast.

BURNOUT CYCLE #2

(Recommended for flask sizes larger than 50.8 x 76.2 mm (2” x 3”))

- Load flask into room temperature oven and ramp to 110°C (230°F) over 30 minutes.

- Hold at 110°C (230°F) for 3 hours.

- Ramp to 450°C (842°F) over 1 hour (60 minutes).

- Hold at 450°C (842°F) for 2 hours.

- Ramp to 780°C (1436°F) over 2 hours.

- Hold at 780°C (1436°F) for 4 hours.

- Reduce temperature to desired flask temperature for casting.

- Hold flask temperature for casting for 2 hours.

- Cast.

RAPID BURNOUT #1

(For use with small flasks less than 50.8 x 50.8 mm (2” x 2”) with one or two prints on tree)

- Load flasks into oven pre-heated to 150°C (302°F).

- Hold at 150°C (302°F) for 2 hours.

- Ramp to 450°C (842°F) over 1 hour.

- Hold at 450°C (842°F) for 30 minutes.

- Ramp to 780°C (1436°F) over 1 hour.

- Hold at 780°C (1436°F) for 2-3 hours (depending on thickness of design).

- Reduce oven to flask temperature for casting.

- Hold flask temperature for casting for 1 hour.

- Cast.

RAPID BURNOUT #2

(For use with flask sizes less than 3” x 4”) Observe recommended bench-set time.

- Load flasks into oven pre-heated to 550°C (1022°F).

- Hold at 550°C (1022°F) for 1 hour.

- Increase temperature to 780°C (1436°F) within 2 hours.

- Hold at 780°C (1436°F) for 4 hours.

- Reduce temperature to desired flask temperature for casting.

- Hold flask temperature for casting for 1 hour.

- Cast.

Ultra 4 Hour RAPID BURNOUT #1

- Ramp to 720 C

- Hold for 1-2 Hours

- Ramp down to casting tempreature and hold for 1-2 Hours

- Cast

4Melt Castable Resin: Redefining Jewelry Design

ProtoResins introduces 4Melt Castable Resin, a revolutionary material that reimagines the jewelry-making process. Unlike traditional castable resins, 4Melt boasts a unique wax-like melting behavior, simplifying mold removal and minimizing damage. This innovative resin captures intricate details with precision, producing flawless metal castings. Its high-temperature tolerance allows for casting with a wider range of metals, expanding your creative possibilities.

ProtoResins: Empowering Jewelry Excellence with 4Melt Castable Resin

ProtoResins is more than a materials supplier; we're your strategic ally in revolutionizing jewelry design through 3D printing. Our commitment extends beyond providing exceptional materials like 4Melt Castable Resin. We offer a comprehensive support system, including expert guidance and in-depth resources, to empower your creative vision. From material selection to casting techniques, our team is dedicated to assisting you at every stage. By combining the power of 4Melt with our unwavering support and the precision of 3D printing, you will elevate your jewelry business to new heights.

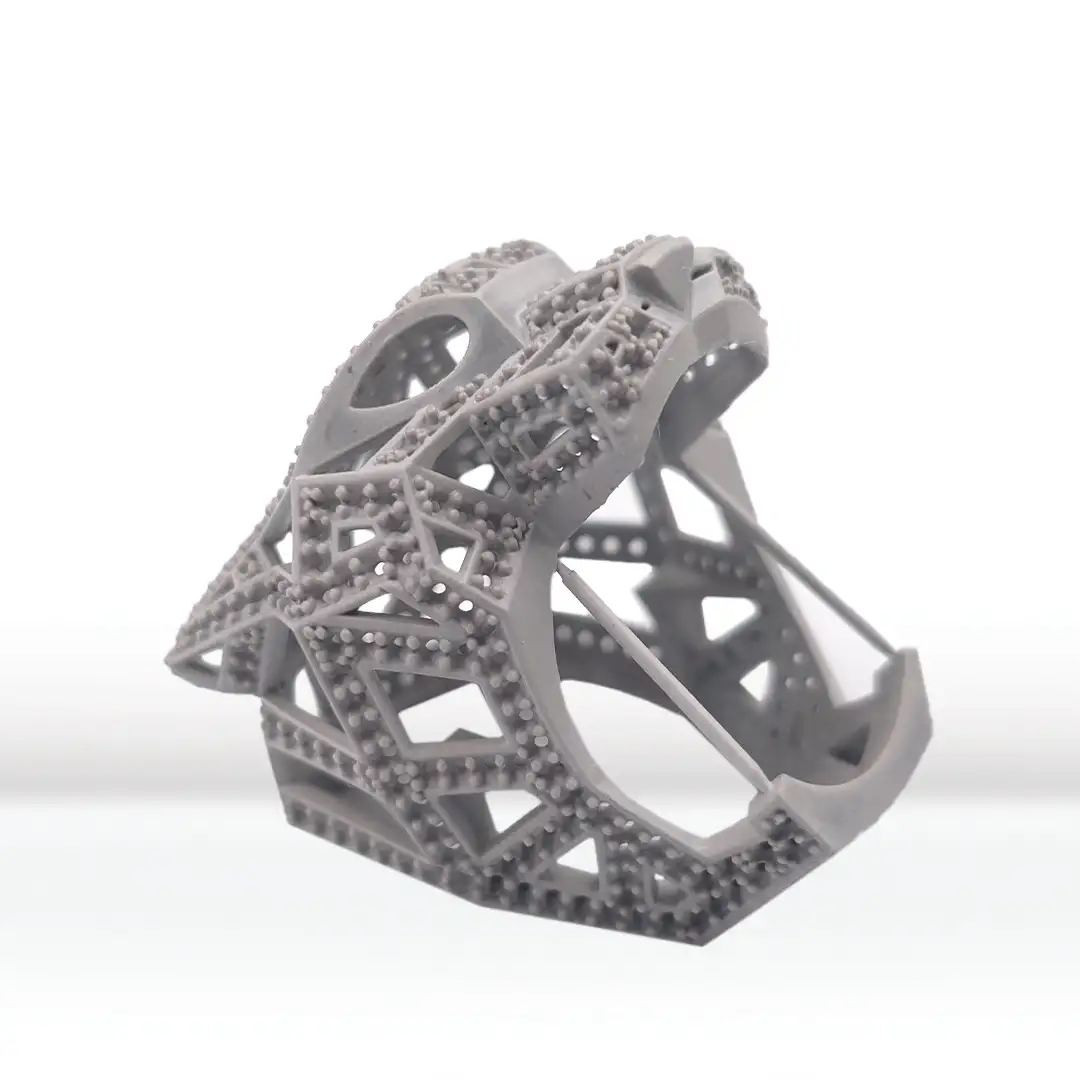

Elevate Your Jewelry Designs with Promould Resins

ProtoResins offers Promould Resins, a new technological breakthrough in making fine jewelry moulds. Intended for use with 3D printers, Promould provides the highest precision and detail that will express your creativity. Experience improved efficiency in that molds are developed earlier and with compatibility with conventional casting systems. Whether it is intricate enameled designs or extravagant single pieces, Promould will help to incarnate your dreams.

Promould Resins: Perfecting Your Jewelry Designs

ProtoResins is dedicated to providing you with the tools and support needed to bring your jewelry vision to life. It also applies to excellent functional components such as Promould Resins which form the foundation of that commitment. For our clients, we provide professional advice, help with the work and useful links. This is because our team of professionals in the relevant industries fully dedicate their enthusiasm to your progress. Our company is here to make the process of jewelry designs through 3D printing efficient that initiates from the choice of materials in Industry to methods of casting. With Proto Resin’s Promould Resins andr full backing, you can achieve the jewelry designs that allow you and your audience to dream.