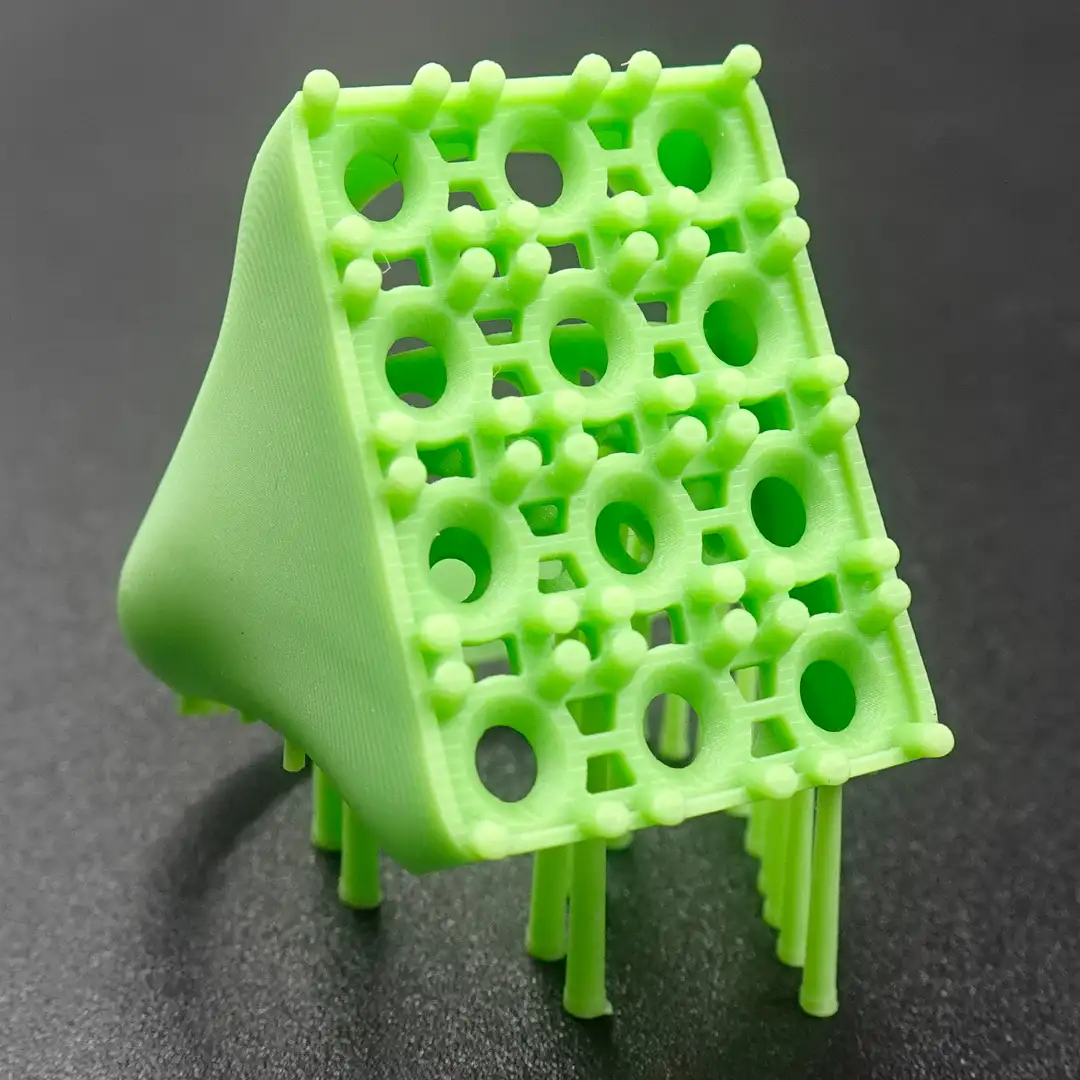

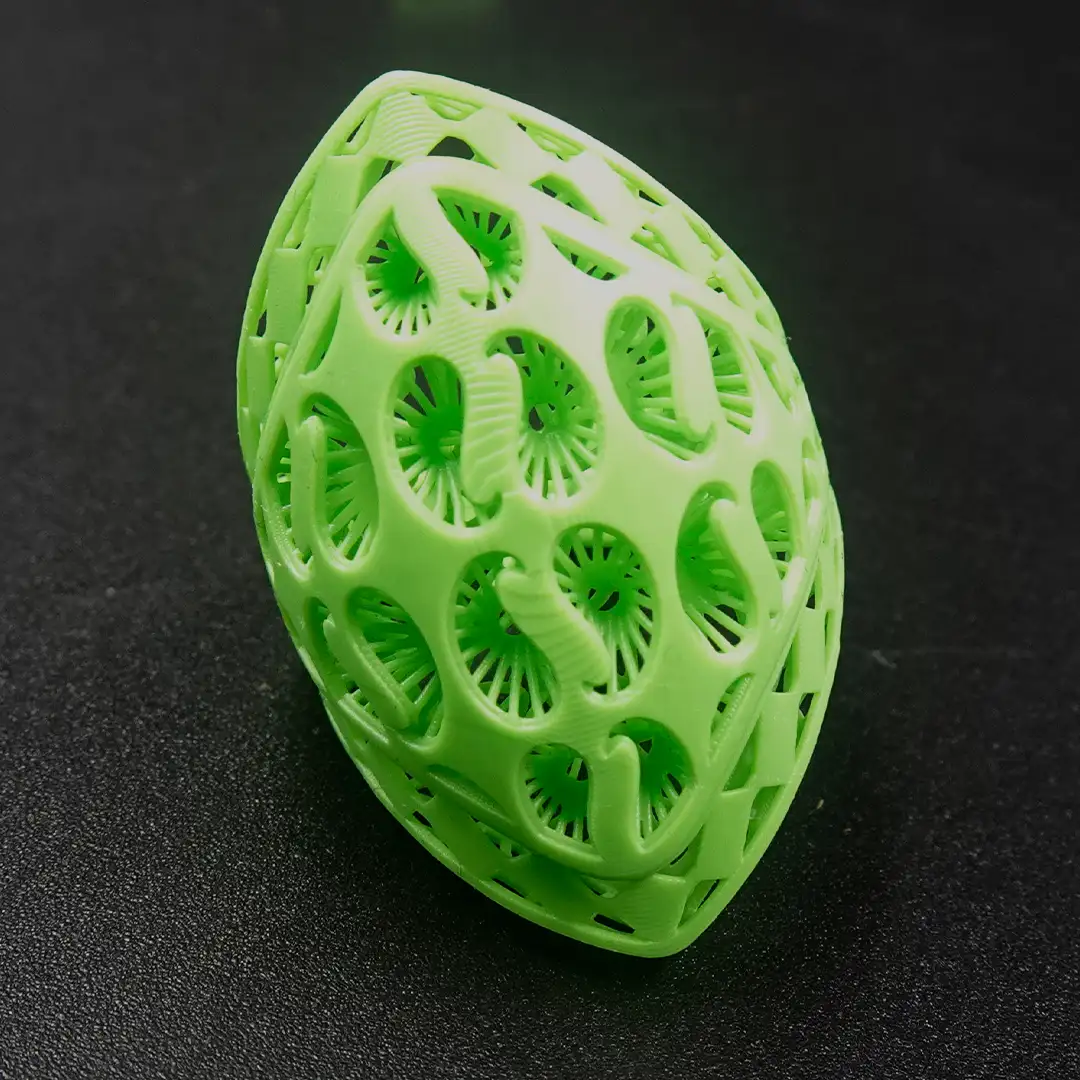

Velvet, the advanced Castable Resin for jewelry manufacturing, offers unparalleled detail, surface smoothness, and ease of integration with your 3D Printing and Casting setup. It can be used on all DLP and LCD Printers. Born from precise research and development, Velvet offers unmatched versatility in our Resin line, delivering ash-free burnout in various investment burnout procedures. Essential for jewelry manufacturers, Velvet is a must-have Resin in your casting arsenal. Upgrade your production process with the next generation of Castable Resins.

-

DLP/LCD Compatible

-

Smoother Surfaces

-

Fusion & Standard Designs

-

No Post Curing

-

No Shrinkage

-

Smooth Casting

Information

Technical Details

| Filigree | Fusion | Standard | Solid Parts | Chains | |

|---|---|---|---|---|---|

| Printability |

Filigree

|

Fusion

|

Standard

|

Solid Parts

|

Chains

|

| Castability |

Filigree

|

Fusion

|

Standard

|

Solid Parts

|

Chains

|

| Property | Value | Standard |

|---|---|---|

|

Property

Density |

Value

1.09 gram/cm3 |

Standard

ASTM D1475-13(2020) |

|

Property

Tensile Strength |

Value

10.99 MPa |

Standard

ASTM D638-14 |

|

Property

Flexural Strength |

Value

19.94 MPa |

Standard

ASTM D790-02 |

|

Property

Flexural Modulus |

Value

353.75 MPa |

Standard

ASTM D790-02 |

|

Property

Shore D Hardness |

Value

73 |

Standard

ASTM D2240-15(2021) |

|

Property

Viscosity |

Value

27.35 Seconds |

Standard

DIN 53211-4 |

|

Property

Color |

Value

Lime Green |

Standard

- |

Printing Instructions

- Make sure to Pre-Heat up to 45C the Resin and shake the bottle for 30 seconds before pouring into the Tray.

- If the Resin is sitting on the tray for longer Periods, Make sure to Mix it with Silicone Spatula Timely.

- It is a good practice to filter the Resin after every Job.

- It is suggested to Pre-Scale the model by 3% to compensate for shrinkage in Extra Light Designs.

Washing Instructions

- It is recommended to use Ethyl Alcohol 99% for washing the prints.

- While washing the prints do not soak Printed models in alcohol for more than 20 seconds.

- Always used compresses air for drying the Printed Models

- Using Ultra Sonic or any other automatic washing equipment don’t soak more than 30 seconds.

- Make sure that Printed Model is clear of any residue resin or alcohol after washing and drying.

Investment Mixing

Proto Resins recommends the following Investment Powders:

- Prestige Optima by Certis

- Ransom and Rundolph's Plasticast

- G-Mix by Gesswein

- X-Vest by Bluecast

Investing and casting from resin prints can be tricky, to say the least. The following recommendations are meant to assist our customers in obtaining the best possible casting results when investing and casting from resin prints.

It is recommended to use a 37/100 water to powder ratio for investing large, thicker prints, and a 38/100 ratio for lighter, smaller prints. Using more water will create a weaker investment mold for burning out resin.

After investing is completed, and before proceeding with burnout, allow invested flasks to sit (bench-set) undisturbed in a vibration-free area for a minimum of 3 to 4 hours (depending on flask size). (3 hours for flask sizes less than 3” x 4” (76.2 x 101.6 mm) and up to 4 hours for larger flask sizes. Drying out the investment and removing too much moisture can lead to mold cracks and metal flashing.

It is advised to use Investment Brands that are exclusive for Resin Casting and pay special attention to the manufacturer’s instructions as well.

Burnout Cycles

BURNOUT CYCLE #1

(Recommended for flask sizes less than 50.8 x 76.2 mm (2” x 3”))

- Load flask into room temperature oven, and ramp to 150°C (302°F) over 30 minutes.

- Hold at 150°C (302°F) for 3 hours.

- Ramp to 750°C (1382°F) over 3 hours.

- Hold at 750°C (1382°F) for 4 hours.

- Reduce oven to flask temperature for casting.

- Hold flask temperature for casting for 2 hours to stabilize temperature throughout the mold.

- Cast.

BURNOUT CYCLE #2

(Recommended for flask sizes larger than 50.8 x 76.2 mm (2” x 3”))

- Load flask into room temperature oven and ramp to 110°C (230°F) over 30 minutes.

- Hold at 110°C (230°F) for 3 hours.

- Ramp to 450°C (842°F) over 1 hour (60 minutes).

- Hold at 450°C (842°F) for 2 hours.

- Ramp to 780°C (1436°F) over 2 hours.

- Hold at 780°C (1436°F) for 4 hours.

- Reduce temperature to desired flask temperature for casting.

- Hold flask temperature for casting for 2 hours.

- Cast.

RAPID BURNOUT #1

(For use with small flasks less than 50.8 x 50.8 mm (2” x 2”) with one or two prints on tree)

- Load flasks into oven pre-heated to 150°C (302°F).

- Hold at 150°C (302°F) for 2 hours.

- Ramp to 450°C (842°F) over 1 hour.

- Hold at 450°C (842°F) for 30 minutes.

- Ramp to 780°C (1436°F) over 1 hour.

- Hold at 780°C (1436°F) for 2-3 hours (depending on thickness of design).

- Reduce oven to flask temperature for casting.

- Hold flask temperature for casting for 1 hour.

- Cast.

RAPID BURNOUT #2

(For use with flask sizes less than 3” x 4”) Observe recommended bench-set time.

- Load flasks into oven pre-heated to 550°C (1022°F).

- Hold at 550°C (1022°F) for 1 hour.

- Increase temperature to 780°C (1436°F) within 2 hours.

- Hold at 780°C (1436°F) for 4 hours.

- Reduce temperature to desired flask temperature for casting.

- Hold flask temperature for casting for 1 hour.

- Cast.