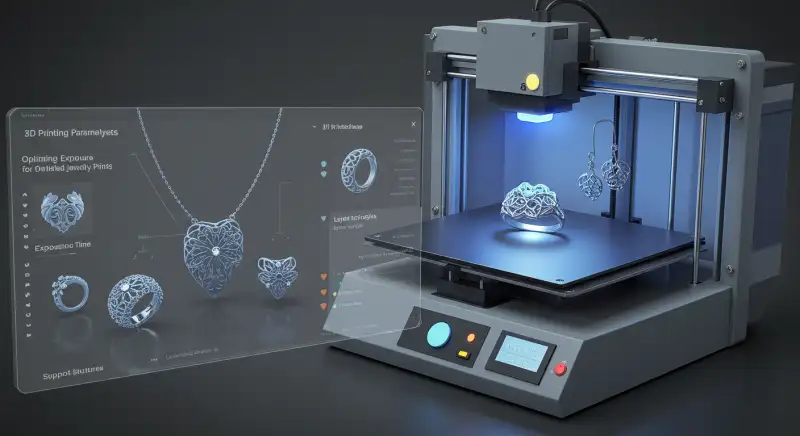

3D Printing Parameters Analysis: Optimizing Exposure for Detailed Jewelry Prints

Creating high-precision jewelry with resin 3D printing demands more than just the right hardware. Achieving clean, accurate, and consistent results starts with one critical factor, i.e., exposure. Proper exposure settings are essential when printing fine details like prongs, filigree, and engravings. In this blog, we focus on how exposure parameters influence print quality and how we optimize them for flawless jewelry production.

Understanding Exposure in Resin 3D Printing

Exposure is the time each layer is cured under UV light. It directly affects resolution, detail sharpness, and structural strength. In jewelry applications, even a small variance in exposure can distort micro-features or weaken parts. We calibrate exposure carefully to maintain the integrity of each design element.

Key Exposure Parameters That Impact Jewelry Prints

1. Bottom Layer Exposure Time

Bottom layers anchor the print to the build plate. We use extended exposure for these layers to ensure strong adhesion and reduce the risk of print detachment.

2. Normal Layer Exposure Time

Each successive layer needs precise exposure to capture small shapes and surfaces. We adjust exposure time based on resin type and layer height to maintain definition without over-curing.

3. Light-Off Delay

After each layer cures, a brief pause lets the resin settle. We apply a light-off delay to prevent layer shifting and ensure clean edge formation.

The Role of Resin and Printer Type

Different resins respond uniquely to UV light. Our team always matches resin specifications with printer capabilities, so we tailor exposure settings based on the printer model to avoid over-curing or detail loss.

Calibrating for Fine Jewelry Prints

Every new resin or printer setup goes through our exposure calibration process. We run test models with micro details and evaluate the results. This step allows us to fine-tune exposure to get sharp edges, clean cavities, and consistent wall thickness, crucial elements in jewelry production.

Balancing Detail and Durability

Jewelry designs often involve fragile structures. We balance exposure time to preserve these details while ensuring parts remain strong and functional. Overexposure can fuse delicate areas; underexposure may cause incomplete curing. We find the middle ground that protects both appearance and strength.

Conclusion

Optimizing exposure in resin 3D printing is not guesswork, it’s a precise, technical process. For detailed jewelry prints, we rely on tested parameters, calibrated equipment. When exposure is controlled, we deliver jewelry models with unmatched clarity, accuracy, and strength, ready for client approval or direct casting.