Casting Data & Assessment: Refining Filigree Jewelry with Silk Wax Resin and Silver

Introduction

We conducted this research trial as part of our ongoing efforts to refine jewelry casting methods and document precise results for future reference. This specific study, identified as SL-M-W-14 (After Casting), focused on producing filigree jewelry using Silk Wax resin and pure silver metal. The trial allowed us to test adjustments in temperatures, burnout cycles, and additives to achieve cleaner surfaces, sharper details, and improved casting reliability. The information below presents every detail of the setup, process, and outcome so that our customers and partners can rely on our findings as a reference.

Casting Details

- Jewelry Type: Filigree

- Resin Type: Silk Wax

- Investment Type: Optima Prestige

- Investment Bag Open Date: 21/05/2025

- Metal: Pure Silver

- Alloy Code: Legor 8F928CH

- Flask Size: 3.5 x 5 inch

- Tree Type: Manual Casting M. Program 2

- Tree Size: 3 x 3 inch

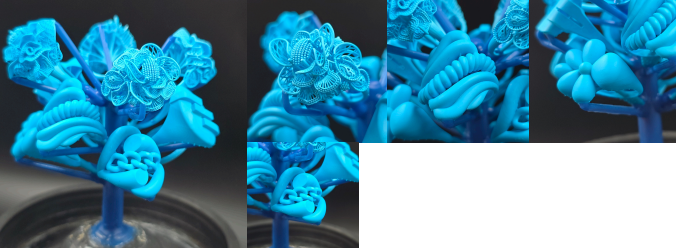

Casting Tree Before Casting

Casting Environment

- Overpressure: 3 Bar

- Pressure (Main Gauge): 4.5 Bar

- Metal Casting Temperature: 1150°C

- Flask Casting Temperature: 715°C

- Casting Delay (Machine): 1 second

- Flask Bench Rest Time: 2 hours

Burnout Process

The burnout schedule was carefully followed to ensure complete resin removal and to avoid microporosity:

- Set 1: 110°C for 2 hours

- Set 2: 780°C for 5 hours

- Set 3: 715°C for 1 hour

- Set 4: Casting temperature 715°C

- Total Cycle: 8 hours

Additives Used

i. Borax: Applied to prevent invisible oxidation during the casting process.

Materials & Measurements

- Total Weight of Water (for investment mixing): 380 (g/mL as per sheet)

- Weights (as recorded during trial):

- Tree Weight (RP): 12.5 g

- Alloy Weight: 137.5 g

- Pure Silver Weight: 127.1875 g

- Silver Alloy Weight: 10.3125 g

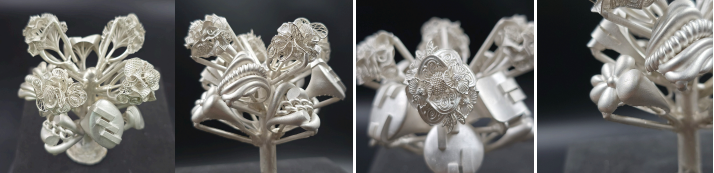

Before Vapor Blasting

Results

The casting trial was reported as successful, with results described as slightly better than SL-M-W-10. Adjustments in metal and flask temperatures contributed to improved surface finish and metal flow.

The images before vapor blasting showed slight roughness on the filigree surface, with minor investment residues visible in delicate areas. After vapor blasting, the pieces exhibited a smooth, clean surface with sharper definition in the fine filigree patterns. The fine wire-like structures maintained their shape, and edges appeared crisp without visible porosity. The surface looked smooth. The improved finish highlighted the effectiveness of the burnout schedule and the controlled casting parameters.

Compared to earlier trials, the metal displayed fewer signs of oxidation, thanks to the addition of Borax. The overall integrity of the tree remained intact, with even distribution of silver across all branches. The detail retention was particularly noticeable in smaller sections of the filigree design, demonstrating the process stability.

After Vapor Blasting

Conclusion

This casting trial demonstrated consistent and enhanced results in producing high-quality filigree jewelry using Silk Wax resin and pure silver alloyed with Legor 8F928CH. The use of controlled burnout, optimized casting temperatures, and Borax additive minimized oxidation and improved the surface outcome. Visual evidence from the vapor blasting stages confirmed clean surfaces, sharper details, and a stable structure.