Using high-quality investment materials is crucial when casting 3D-printed jewelry designs. In this blog, we explore how premium investment brands improve surface finish, reduce casting defects, and ensure the fine details of your designs come out flawlessly. Learn why cutting corners on investment quality can cost you more in the long run.

When it comes to 3D printing jewelry, choosing the right resin can make all the difference in quality, detail, and casting success. In this post, we break down the key differences between photopolymer and meltable castable resins—exploring their strengths, limitations, and best use cases. Whether you're creating intricate prototypes or ready-to-cast pieces, this guide will help you make the right choice for your next jewelry project.

Three investments lead the market for flawless jewelry casting: R&R Plasticast captures ultra-fine details (0.2mm), Certus excels with white gold/3D resins, and Gesswein G-Cast RP offers unmatched thermal stability (1,526°F). Always test with a Celtic knot sample first.

The world of jewelry design is evolving at lightning speed, and 3D printing technology is fueling this transformation. At the forefront of this innovation is castable resin — a game-changing material that empowers designers to bring intricate visions to life with unmatched precision.

ProtoResins Castable Resins are a top choice for jewelry designers and manufacturers, offering unmatched precision and clean burnout properties for creating intricate, high-quality jewelry and prototypes. These resins are specially designed for 3D printing, making them ideal for the lost-wax casting process

Castable resins for 3D printers have revolutionized small-scale jewelry production, offering precision, versatility, and efficiency. These resins capture intricate details, burn out cleanly for flawless casting, and streamline the production process, reducing costs and turnaround times. With the freedom to create complex designs and compatibility with precious metals like gold and silver, castable resins are a game-changer for jewelers.

3D printing has transformed jewelry and prototyping, with castable resins for 3D printers leading the way. These resins burn out cleanly, making them ideal for casting. But how do you choose the right one? Test print quality, burnout performance, and printer compatibility to find the perfect resin for your needs. The right choice saves time, reduces waste, and ensures flawless project results.

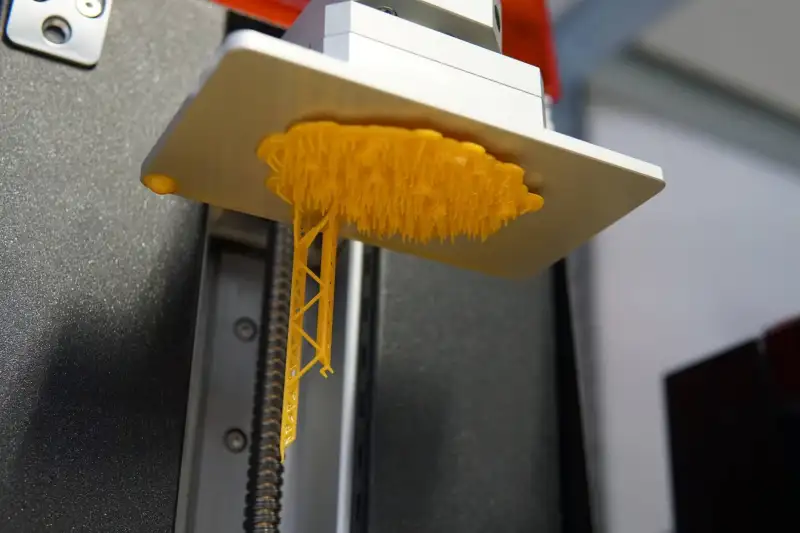

Strong adhesion is key to successful resin 3D printing, especially for detailed jewelry molds or complex designs. Poor adhesion can lead to failed prints and wasted resin. In this blog, we explore common causes like unlevel build plates and incorrect exposure settings and share proven solutions to ensure flawless prints every time. Perfect your resin 3D printing with these expert tips.

Castable resins are the key to flawless 3D-printed jewelry molds for gold, silver, and platinum. Learn why they are the best resin for jewelry and how to achieve perfect prints every time. From printer settings to burnout tips, this guide helps you create professional-quality molds for custom rings, necklaces, and more.

Resin casting is a versatile process used in jewelry, dentistry, and prototyping, but challenges like surface imperfections, incomplete burnout, and mold cracks can arise. In this blog, we’ll explore common resin casting issues, their causes, and practical solutions to help you achieve flawless results every time. Perfect your craft and tackle challenges with confidence