The Role of Borax in Silver Casting & Understanding Invisible Oxidation

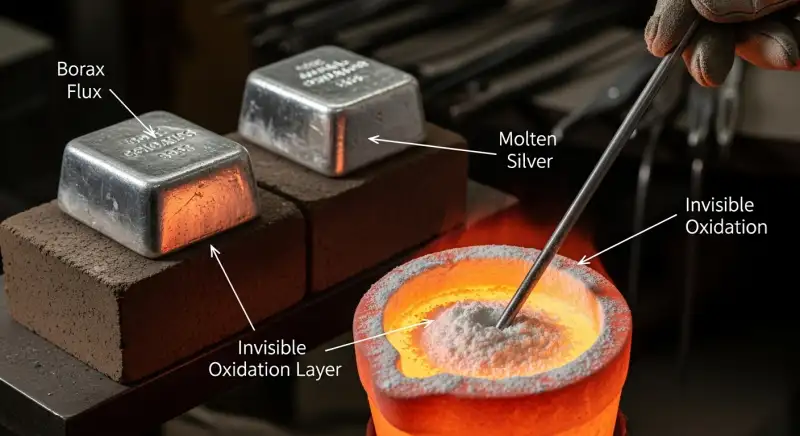

Silver casting demands precision. In automated systems like Galloni’s induction-based vacuum and pressure casting machines, every detail affects the final output. From the crucible material to the melt temperature, even small variations can impact quality. Among these variables, Borax plays a vital but often underused role. More than a traditional flux, it protects silver from invisible oxidation, a hidden issue that can compromise casting integrity even in controlled conditions.

This guide explains what Borax does, how invisible oxidation occurs, and how both affect your results in silver casting.

What Is Borax and Why Does It Matter in Casting

Borax, or sodium borate, is a mineral compound used in metal casting as a flux. In silver casting, it performs two key functions:

- It dissolves metal oxides and impurities during the melting phase.

- It forms a protective glassy film that shields molten silver from air exposure.

We count on this protective layer to stabilize the molten metal and maintain a clean melt surface. In systems that use induction heating and closed chambers, Borax helps us keep the melt free from reactive contact with gases inside the furnace.

Understanding Invisible Oxidation in Silver Casting

Most casters are familiar with visible oxidation. It appears as a dark crust or residue on the metal surface. But invisible oxidation is more subtle and damaging. It forms a thin oxide film that’s not visible but can:

- Disrupt fluid flow and prevent full mold filling

- Create micro-porosity or internal shrinkage defects

- Interfere with soldering, polishing, and plating

- Weakened mechanical properties in layered or multi-metal castings

Invisible oxidation often appears in silver alloys with copper, especially when melt temperatures go beyond the optimal range. Even in nitrogen or argon environments, residual oxygen can trigger this problem. Without Borax, we risk poor quality even when every other setting appears correct.

How Temperature Affects Oxidation

Silver melts at 961°C. But most casting systems heat silver between 1050°C and 1100°C to improve metal flow. This range improves casting, but it also increases reactivity. At higher temperatures:

- Silver absorbs more gases from the atmosphere

- Copper in sterling alloys starts to oxidize or vaporize

- Oxide layers form rapidly, affecting casting quality

- Overheating causes grain growth and surface defects

For this reason, managing temperature and using Borax together gives us better control over the final casting quality.

How Borax Functions Inside an Automatic Casting Machine

Induction casting machines like Galloni use a combination of controlled heat, vacuum, and pressurized gas. Borax works well in this environment due to its melting behavior and chemical action.

During Melting

Borax melts before silver and floats on top of the molten metal. It reacts with metal oxides, turning them into a glass-like slag. This slag captures impurities and prevents further oxygen contact.

In Inert Gas Environments

Even with argon or nitrogen, some oxygen may remain in the chamber. Borax traps oxides at the melt surface, especially near the crucible walls and corners where gas flow may be uneven.

After Pouring

The slag stays in the crucible while only clean metal flows into the mold. This leads to fewer surface issues, better mold fill, and less post-cast cleanup.

Step-by-Step Guide: Using Borax in Automated Silver Casting

1. Prepare the Crucible

Apply a light coat of Borax to a clean graphite or ceramic crucible. Heat it slightly to form a smooth glaze. This step prevents contamination from past cycles.

2. Load Clean Silver

Use only cleaned silver alloy. Avoid oxidized scrap unless it has been thoroughly prepared.

3. Apply Borax Powder

Use about 1 to 2 percent of the metal weight in Borax. For example, for 100 grams of silver, use 1 to 2 grams of Borax.

4. Start the Heating Cycle

Begin the induction process. Borax will melt early and float on the silver surface, forming a protective cap.

5. Enable Inert Gas Mode (If Available)

Purge the chamber with nitrogen or argon to limit oxygen exposure.

6. Begin Casting

Run the casting cycle. The Borax remains in the crucible, having completed its role.

7. Post-Cast Cleanup

Let the crucible cool. Remove the leftover slag and clean the crucible thoroughly. Recoat before the next cycle.

Tips for Optimal Use of Borax

- Use refined or anhydrous Borax to avoid moisture and splatter

- Avoid melting silver above 1100°C to reduce oxide formation

- Clean crucibles regularly to prevent Borax buildup

- Always remove contamination from scrap metal before use

Conclusion

In precision casting, invisible oxidation is a hidden challenge. Even when using a vacuum and inert gas, it can still form and ruin a cast. Borax remains one of the most effective defenses. It protects molten silver, improves casting flow, and reduces the need for polishing or repair.

By applying Borax correctly within your induction-based casting system, you reduce defects, control oxidation, and produce sharper, cleaner silver parts. This simple material supports better production efficiency and overall casting quality.